The Most Trusted Source to Buy and Sell Used CNC, Fabrication, and Plastics Machinery

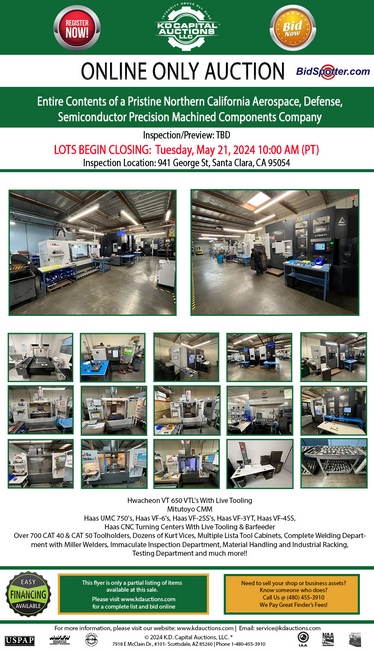

AUCTIONS

Have a Used CNC Machine for Sale?

KD Capital Equipment is one of the largest stocking dealers of used CNC Machines, Plastic machines, and Fabrication Machinery. We are active cash buyers and will buy single machines or entire facilities.

Please click on the button below to submit your equipment information and one of our staff members will contact you with a cash offer right away!

Sell Your CNC MachinesWe Provide the Following Professional Services:

- Used CNC Machinery for Sale

- Used Plastic Machinery for Sale

- Used Fabrication Machinery for Sale

- Machinery Purchasing

- Remarketing

- Appraisals

- Auctions

- Liquidations

- Financing

- Trade-Ins